服务热线

4001-123-456

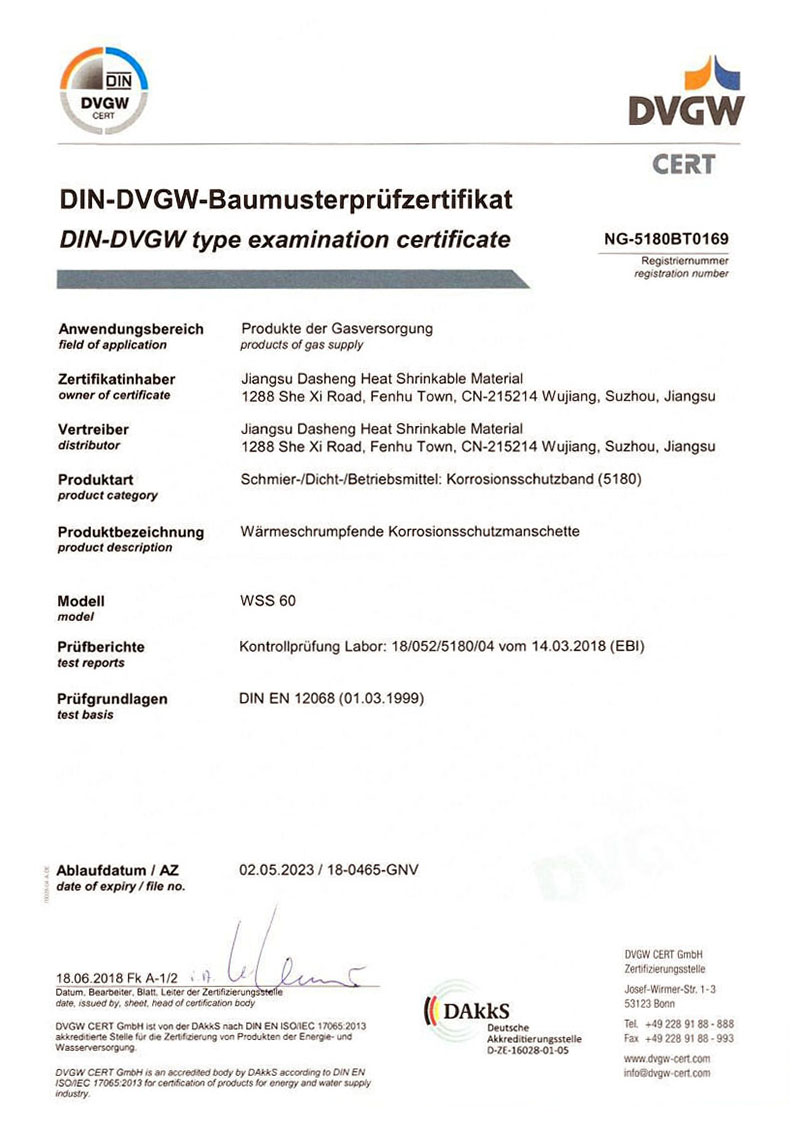

WSS heat shrinkable tape is designed for corrosion protection of field girth weld joint buried and exposed steel pipelines, especially for corrosion protection of oil and gas petrol-pipeline.

WSS provides excellent resistance to cathodic disbondment resulting in effective long-term corrosion protection. The high performance cross-linked backing in combination with a broad of adhesive can be engineered for regular or high stress environments. WSS provides the structural integrity of seal tube, and provides the substrate with durable protection against abrasion and chemical attack.

WSS has a construction of three-layer system, the first layer is two components solvent-free epoxy primer, the second layer is high strength hot melting copolymer adhesive and the third layer is radiation cross-linked high density polyethylene backing.

| WSS(M50) | WSS(60) | WSS(80) | |

| Max. Operating Temperature | 60°C | 70°C | 85°C |

| Applicable Outer Coating | PE, FBE, PP or steel | PE, FBE, PP | PE, FBE, PP |

| Preheat Temperature | 60°C | 75°C | 85°C |

| Derust Grade | Sa2.5, St3.0 | Sa2.5, St3.0 | Sa2.5, St3.0 |

(Standards: GB/T51241, GB/T23257 and other standards)

Heat Shrinkable Tape (Sleeve) - Instruction Manual

Heat Shrinkable Tape (Sleeve) - Instruction Manual| Property | Performance | Standard | ||||

| WSS (M50) | WSS (60) | WSS (80) | ||||

| Primer | ||||||

| Solid Content % | 99.4 | 99.4 | 99.6 | GB/T 1725 | ||

| Cathodic Disbonding (65°C, 48h) m | 5 | 4.8 | 4.3 | GB/T 23257 | ||

| Backing | ||||||

| Tensile Strength MPa | 21 | 24 | 24 | GB/T 1040.2 | ||

| Elongation % | 550 | 550 | 550 | GB/T 1040.2 | ||

| Density | 0.93 | 0.94 | 0.94 | GB/T 29046 | ||

| Dielectric Strength MV/m | 35 | 35 | 35 | GB/T 1408.1 | ||

| Volume Resistivity Ω·m | 4.0×1015 | GB/T 1040 | ||||

| Heat Aging (150°C, 21d) |

Tensile Strength MPa | 17 | 18 | 18 | GB/T 1040 | |

| Elongation % | 480 | 480 | 480 | |||

| Hot Melt Adhesive | ||||||

| Softening Point °C | 78 | 113 | 120 | GB/T 15332 | ||

| Lap Shear Strength MPa | 0.8 | 0.8 | 1.0 | GB/T 7124 | ||

| Brittle Temperature °C | -30°C | -20°C | -15°C | GB/T 23257 | ||

| Heat Shrinkable Sleeve | ||||||

| Shock Resistance J/mm | ≥5 no leakage points | GB/T 23257 | ||||

| Peel Strength N/cm (cohesion) |

to Primer Steel (23°C) | 90 | 160 | 140 | GB/T 23257 | |

| to PE (23°C) | 85 | 110 | 95 | |||

| to Primer Steel (Tmax) | 5 | 8 | 10 | |||

| to PE (Tmax) | 4 | 8 | 10 | |||

| Cathodic Disbonding mm |

23°C, 28d | 8.2 | 5.6 | 4.8 | GB/T 23257 | |

| Tmax, 28d | 12 | 8.6 | 9.4 | |||

| Peel Strength (Tmax Hot Water Immersion 28d) N/cm |

to Primer Steel (23°C) | 52 | 143 | 152 | GB/T 23257 | |

| to PE (23°C) | 56 | 145 | 162 | |||

| Heat Aging (Tmax+20°C, 100d) Peel Strength Retention % |

P₁oo/Po | 86 | 83 | 84 | GB/T 23257 | |

| Paop/P70 | 92 | 91 | 98 | |||